Bead Wire

Tyre bead wire is a copper/ bronze coated wire which is used for the reinforcement of virtually all types of pneumatic tyres such as trucks, buses, cars, motorcycles, etc. The main function of the tyre bead wire is to act as reinforcement and it helps to get a proper grip of the tyre on the rim. The type of tyre and structure of bead rings used, determine the size of bead wire.

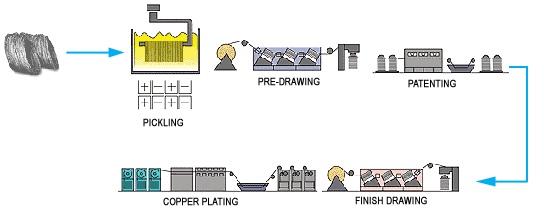

Process

| Property | Definition | Testing Method |

|---|---|---|

| Diameter | The arithmetic average of the maximum and minimum thickness of the wire measured in the same place and measured in millimeter. | A specimen of wire is held on between two parallel anvils of a micrometer. |

| Breaking Force | The maximum force which a test specimen can support during a tensile test of loading to break, expressed in Newton, Kg, etc. | A specimen of wire is clamped in a tensile testing apparatus under a defined Pre-tension and subjected to a constant rate of extension until rupture. |

Tensile Strength |

The breaking load or force of a wire per unit of cross sectional areas of the unstrained specimen expressed ink/mm or N/mm2. |

A specimen of wire is clamped in a tensile testing apparatus under a defined pre-tension and subjected to constant rate of extensions until rupture. |

Torsion |

The number of revolution made by a specific length of wire when twisted until rupture on its own axis in one direction. |

Gauge length of wire test is 100xfd or 8 inches conforming to ASTM -D4975. |

Coating |

Mass of coating |

The weight of coating per unit weight of wire and the composition of the bronze expressed as the percentage of Cu in the total weight of the coating. This is determined using an automatic thickness detector. |

Elongation at break |

The delta increase in length of the test specimen and subjecting it to the breaking force in a tensile test expressed as a percentage of the initial length. |

During the breaking force of determination of the wire, the increase of tyre test length at break will be registered. |

Adhesion Strength |

Pulling required to pull out wire from rubber compound, expressed in Kg/N. |

The test method use in accordance with ASTM D 1871 or a method specified by the customers. The rubber compound used shall be provided by the customers together with relevant information about the time and temperature for vulcanization. |

Proportional limit |

It is the load where the increase of elongation is no longer linear to the increase of load. |

|

Impact Resilience |

Property of wire to recover its original after removal of force causing deformation. |

A test specimen of 42cm long is taken and bent on both side at 1cm distance from end. The sample is released and ratio of initial deflection of wire to deflection is calculated. |

Straightness |

Ability of wire to lie flat on a smooth surface between two parallel lines. |

A specimen of 3mt long is released. The deflection from the centre line is expressed in cm. |

Residual Torsion |

Number of revolution made by a specific length of wire when locked at one end and allowed to turn freely at the other end. |

Initial 3 to 5mt of wire the real is discarded 3 to 10mt length of wire is pulled from the reel holding the bend end tightly. Releases the bend holding the bend end and count the number of turns. |